Our first visit to Guatemala was in December of 2019, when we toured the capital city of Antigua. Episode 51 – Amazing Antigua

That time, we also docked in Puerto Quetzal, a small port town about a 90 minute drive from the capital.

Although we originally planned to simply hang around the port, a couple of days ago we changed our minds and booked a full day escorted tour. I recalled Antigua as being quite beautiful, so revisiting it made sense.

There are two great unpredictables when it comes to shore excursions: weather snd traffic. The weather held today at a beautiful if slightly overcast 20°C/68°F. Unfortunately, an accident on the narrow 2 lane (and no shoulders!) highway from Puerto Quetzal to Antigua meant that our expected 90 minute drive took a full three hours.

Along the s-l-o-w route we passed by fields growing Guatemala’s 5 top economic crops: coffee, cardamom, bananas, plantains, and sugar cane, in that order. We caught glimpses of 3 of the country’s largest volcanoes, although their tops were shrouded in cloud.

We passed through virtually continuous green canopy, much of it almost brushing the sides of the bus on the narrow road, demonstrating how appropriate it is that this country is named Guatemala, “place of trees”.

On a newly paved road, we passed by the same villages that were “Zona Zero” (effectively “ground zero”) for the 2018 earthquake. None of the burned-out homes have been repaired, and the government is not encouraging anyone to do so.

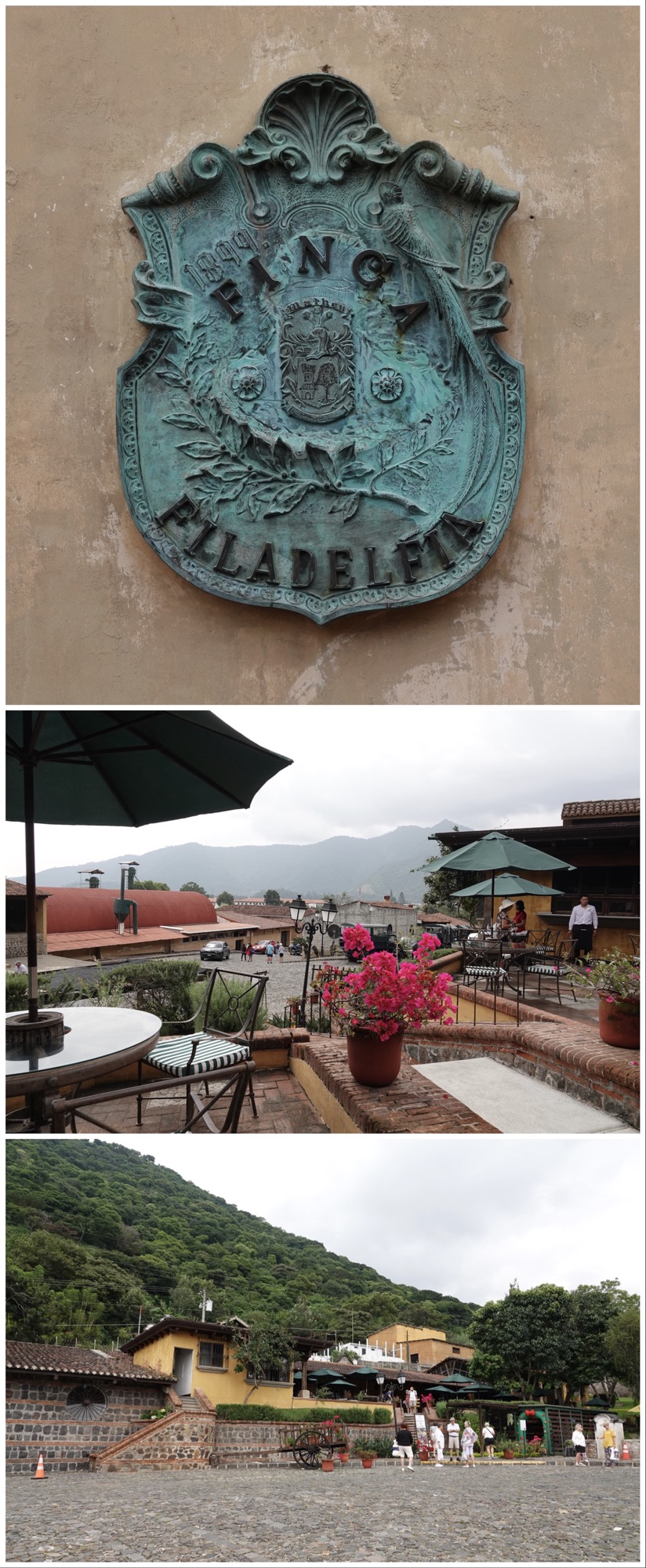

It was all worth it when we reached Finca Filadelfia, the beautiful 700 acre coffee plantation whose name translates as Brotherly Love Farm, and where our guide Faustino (“Tino”) explained the process used by four generations of coffee farmers here since 1870. He reiterated what we’d already learned, that coffee trees are not native to Central and South America, but were brought here in the 1700s from Ethiopia and Kenya as ornamental plants. “Modern” cultivation methods like high altitude shade growing are credited to German immigrants in the 1840s.

The plants at Finca Filadelfia are grown from seed in the family’s own greenhouses. Twelve different distinct varieties of Arabica coffee are grown here, but the coffee beans used for brewing are blends intended to bring out the best flavour.

In the outdoor nursery, we saw tiny two month old plants in their plastic sleeves, carefully nurtured with by-weekly liquid nitrogen and minerals.

Planted behind them were larger one year old plants.

It takes three years for a coffee plant to yield cherries; a plant will bear good fruit for 25 to 30 years, after which both yield and quality decline. When that happens the trees, complete with their roots, are pulled out and mulched for fertilizer and replaced with new plants.

Our guide gently squeezed one of the ripe red cherries to show us the tiny drop of sugar that comes out at the stem end. Agricultural engineers use this squeeze method to extract sugar and measure the sweetness of the cherries, with the ideal level of sugar being 18 to 22 degrees Brix. By comparison, the average Brix value for fresh orange juice is 11.8°Brix.

Several of us got to more firmly squeeze the cherries to pop out two beans from each. Much like the cocoa beans we saw yesterday, the coffee beans are also coated in a slimy mucus, but this time it is sweet! It was the opposite of what I expected: the coating on the raw cocoa beans was fruity and slightly acidic, while the coating on the raw coffee beans was incredibly sweet.

When the coffee cherries have reached their ultimate sweetness, they are ready to be harvested. Not all the beans ripen at the same time, so pickers return to the plants over and over each day during the peak harvesting months of December through early March, choosing only the dark red ones.

Those red coffee cherries, picked by hand in the mountains, come down in huge trucks and are dumped into vats of water. The lighter cherries that rise to the top and float, about 5% of the yield, are skimmed off and become the lower quality beans that are used for commercial “exchange grade”coffees. The heavier cherries that sink to the bottom eventually become premium coffees. Below standard and off grade beans become organic fertilizer and animal feed.

The cherries are then gently pressed to pop the beans out of the outer fruit. The pulp gets used as fertilizer for the fields, or can be used to create sweet coffee jelly, a jar of which we bought and will share with son #2 when we get back to B.C.

The slimy inner beans are allowed to ferment for 24 hours. The mucus is too hard to remove otherwise; fermentation makes it separate easily from the bean. The beans are then washed again, and spread out to dry.

This entire square we stood in gets filled up to 4 inches deep with beans that are naturally sun-dried for a week or more, depending on the strength of the sun. The beans are raked every two hours round the clock to circulate them to ensure that all of them are dry.

Drying removes the moisture down to just 10 to 12%, creating a bean that can now go into initial storage. At this point the bean has a crunchy shell on it, which when removed reveals a bean with a silvery skin. Once that skin is removed, the interior bean is the jade green colour that gave rise to the name “green” beans for the unroasted state.

These green beans are what get shipped worldwide to roasters who create their own blends and choose their own roasting level. At Fina Filadelfia, 40% of their yield remains in house to be custom roasted and sold under their own brand name, R. Dalton. We were told that an over roasted bean will become bitter and acidic (sorry, Tim Horton’s) but that a perfectly roasted bean yields sweet coffee that needs no milk or sugar added.

We all had to don hairnets to walk through the processing building.

Inside there were three vats with different bean capacities (25 pounds, 150 pounds, and 300 pounds), allowing for three different roast levels and different coffee varieties to be kept separate or blended, at the direction of the roaster.

When the beans start to make a popping sound, the master roaster waits for a second pop and then checks the colour every 15 seconds until the perfect roast level is reached. The heat is then turned off and the beans allowed cool for 20 minutes before being transferred into a silo to rest for 24 hours before being ground (or left whole) and fed into the packaging /bagging machine which seals the coffee into 12 ounce bags.

Finca Filadelfia sells their R. Dalton premium coffee on site which has been grown at 3 different elevations: 1800-2200 meters/6000-7000 feet (the most expensive), 1600-1800 m/ 5000-6000 ft, 1300-1600m/4000-5000 ft, and also commercial lower altitude coffees. The red labelled bags are beans grown at the very highest elevation: 2400m/8000 ft. We bought high altitude beans for son #2, and ground coffees for us.

After leaving the processing area, and doffing our hairnets, we passed by warehouses with bags of green beans ready to ship all over the world.

1600 m/5000 feet above sea level.

We enjoyed a wonderful lunch at the on-site restaurant: grilled beef, corn, and potato, served with refried beans, guacamole, tostadas, and fresh warm corn tortillas. The meal finished with a delicious coffee mousse and a cup of the plantation’s truly wonderful premium coffee.

The next part of our tour was to be in Antigua. Had the bus trip inland been the usual 90 minutes, we would have had 2-1/2 hours in the city. As it was, we had a rushed hour – 40 people trying to hear one guide over the noise of street vendors and traffic. Ted took almost no pictures, but we still have the great ones from our first visit (linked in the first paragraph) and the city really has not changed in 4 years.

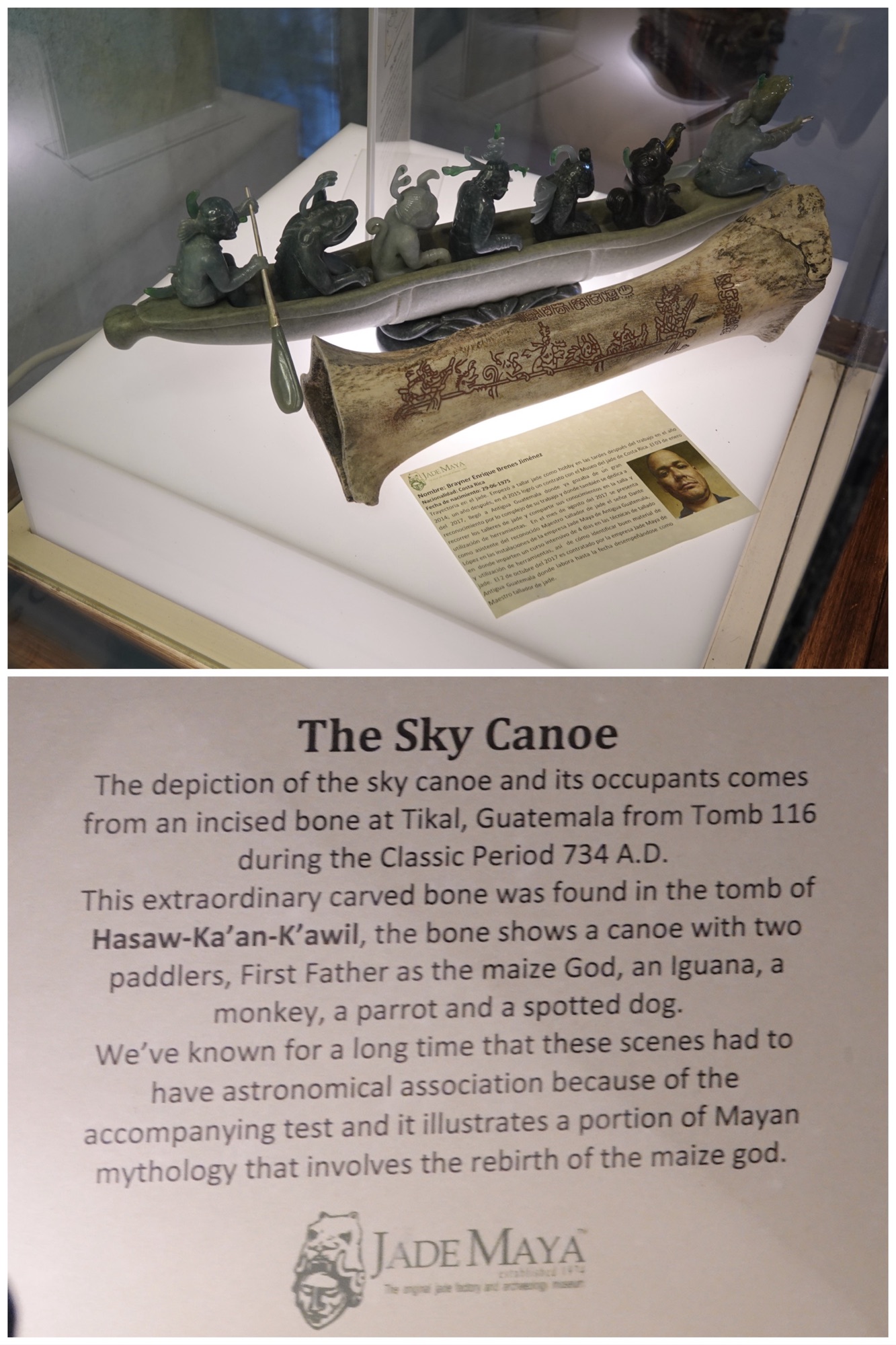

We did re-tour the jade museum/store though, this time meeting the woman who, with her husband, in 1974 found jade deposits here and helped create a modern jade industry. Of course, the Olmec and Maya had for millenia used jade for adornment and statues, and revered it as bestowing a measure of immortality on those who wore it.

Then it was time to get back on the bus and back to the ship, this time completing the trip in the expected 90 minutes – only it wasn’t the same bus we came in on. The air conditioning on ours had malfunctioned, necessitating a replacement being found while we were at Finca Filadelfia.

Walking back through the cruise terminal welcome centre I couldn’t resist petting the jaguar statue. That majestic cat is synonymous with Guatemala.

And so ends another day: pizzas on the aft deck under the moonlight, coffees in the Crow’s Nest, and an early night.

Tomorrow’s a sea day. A book beckons….

loved your detailed review of the coffee plantation processes.

LikeLiked by 1 person

What a fabulous day! Aren’t you glad you changed your mind and took the shore tour to the plantation. A very fascinating description of the coffee process, too.

LikeLiked by 1 person

What a fabulous day! Aren’t you glad you changed your mind and took the shore tour to the plantation. A very fascinating description of the coffee process, too.

LikeLiked by 1 person

Sometimes the last minute decisions are the best ones!

LikeLike